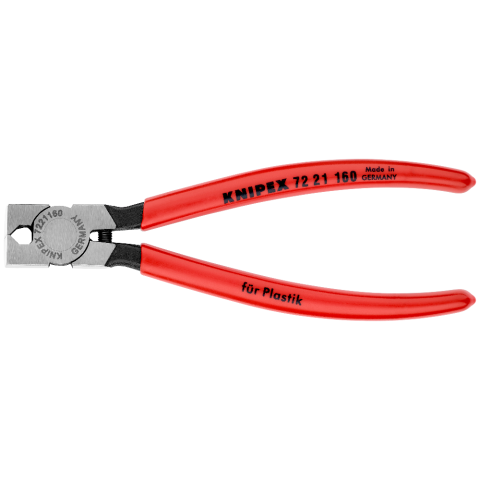

72 21 160Diagonal Cutters for plastics

- Cutting face flush

- For nearly flush cutting of moulded plastic components from sprues

- Cuts soft materials such as lead in a flush cut

- With opening spring

Diagonal cutters for plastic and other soft materials

Why special diagonal cutters are needed for plastic

Diagonal cutters for wire have bevels on the cutting edges, producing a wedge-shaped cut towards the centre of the cut product. The wire ends then have wedge-shaped cut surfaces. A flush, smooth cut is desired when separating moulded parts and sprues, however, which creates the least finishing work when deburring. The cutting edges of the Knipex 72 21 160 diagonal cutters have no bevel towards the component, but are surface ground. For this reason, the sprue is cut off directly on the moulded part. The cutting edge runs parallel to the component.

Cutting edges at a 90° angle for deburring in poorly accessible areas

Due to their cutting faces at an angle of 90°, the Knipex 72 21 160 diagonal cutters are suitable for work perpendicular to the component. This approach is necessary when access from the side is not possible, as with angled plastic mould parts or machine components. Plastic parts are separated cleanly and flush from sprue after demoulding by the surface ground cutting faces. Plastic injection moulds are separated; sprue residues are removed even from areas that are hard to reach.

With opening spring to relieve strain on the user – compact and stable

In many cases, work steps in plastic injection moulding and production processes repeat. Users who frequently separate sprues from moulded parts therefore appreciate the opening spring on the 72 21 160, which saves one hand movement during each cutting operation The Knipex diagonal cutters for plastic have been designed for many years of work in plastic injection moulding and other industrial areas. We forge them from vanadium electric steel. Warming them and then quenching them in oil gives them their high strength.

Compact diagonal cutters for plastic and soft materials such as lead

Cutting edges at an angle of 90°; areas that are difficult to access can be processed well

For the smooth, flush cutting of sprue as arises during injection moulding

Surface ground cutting edges (no bevel)

Handles coated with non-slip plastic

Vanadium electric steel, forged, oil hardened

Length 160 mm

Net weight 165 g

Knipex diagonal cutters for plastic and soft materials

One can see how good diagonal cutters are by the cut. This also applies when cutting plastic.

In addition to the quality forged parts made of vanadium electric steel, the most important quality criteria at Knipex include the precise machining of the tool steel manufactured in Germany. The material is cut flush using the surface ground cutting edges.

Thanks to their long tool life, Knipex diagonal cutters produce permanently accurate cuts.