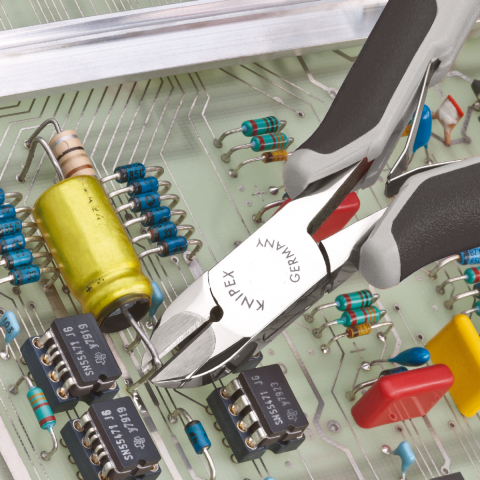

77 02 135 H ESDElectronics Diagonal Cutter with carbide cutting edges ESD

- For extreme demands on cutting pliers caused by hard or tough materials, e.g. piano, nickel, tungsten and diode wire, such as those used more frequently in the electronics and aerospace industries

- Always the right cutting tool, even with the hardest material

- Precision carbide metal cutting edges soldered into forged blanks

- Sturdy, zero-backlash box joint

- Hardness of the carbide cutting edges 80 – 83 HRC

- Pliers with carbide metal cutting edges have a substantially longer service life than such with conventional cutting edges

- Constantly reliable cutting results due to the avoidance of cutter deformations caused by overloading

- High cost saving due to longer service life of the pliers

- Electrically discharging handles - dissipative

Precise cutting of hard wires – piano, nickel, tungsten or diode wires

Compact dimensions – extraordinary cutting capacity

Unlike other diagonal cutters for electronics, the Knipex 77 02 135 H ESD electronics diagonal cutter combines a precision tool and high-performance pliers with ESD protection. At 135 mm and 115 g, it is compact and lightweight. Its precision carbide cutting edges are also suitable for particularly hard and tough types of wire. A cutting edge hardness of 80–83 HRC means it cuts soft wire up to Ø2.2 mm, hard wire up to Ø1.2 mm and piano wire up to Ø0.8 mm. The short pliers head offers strong leverage. This makes it perfect for power delivery on the cutting edges and controlling manual force. Overall, this makes it ideal for use in confined spaces, e.g. for PCBs or in safety casings.

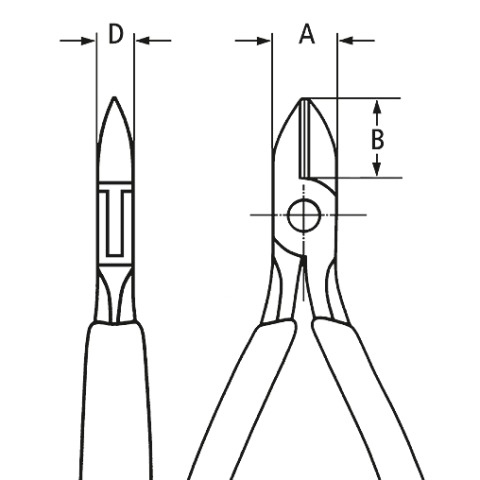

Zero-backlash box joint. High cut quality and durability

The Knipex 77 02 135 H ESD electronics diagonal cutter has a box joint. The inside of both pliers handles is guided. This prevents tilting. Rivets only undergo shearing stress. Result: higher-quality cutting operations, long service life. The carbide cutting edges exceed the hardness values typical of conventional pliers with 80–83 HRC.

ESD protection against electrostatic discharges; corrosion protection

In electronics diagonal cutter 77 02 135 H ESD, electrostatic energy is discharged in a controlled way via the handles. Instead of chrome plating, the electronics diagonal cutter is mirror polished with a fine film of oil to prevent corrosion. This also avoids the risk of faults on PCBs due to chipped chrome parts.

Electronics diagonal cutter, ESD protection in aerospace industry

Cutting values: soft Ø2.2, medium-hard Ø1.6 mm, hard Ø1.2 mm, piano Ø0.8 mm

Box joint

Mirror polish plus fine oil film protect against rust

Forged, oil-hardened with special quality special tool steel

Inset carbide cutting edges with a hardness of 80–83 HRC

Handles, multi-component grips

Length 135mm; Net weight 115 g

Electronics diagonal cutter "H" for high performance, e.g. aerospace industry

Knipex offers a wide range of box joint electronics diagonal cutters for applications in electronics and precision equipment and – with models using precision carbide cutting edges – also for applications such as the aerospace industry. These cutters are characterised by high precision and functionality – plus the proverbial Knipex durability. Professionals who use tools a lot every day expect a quality that enables them to work easily and safely and that can withstand many years of tough service. All pliers from Knipex embody over 135 years of specialist expertise.

Great cutting, long service life

Precision carbide cutting edges (80–83 HRC) are soldered into the forged blanks of the Knipex 77 02 135 H ESD.