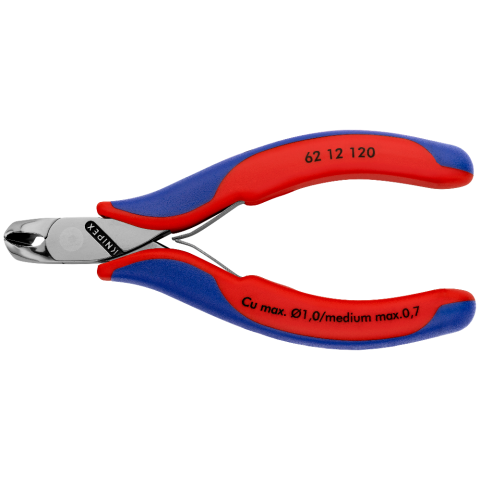

62 12 120Electronics Oblique Cutting Nipper

62 12 120

Electronics Oblique Cutting Nipper

- With cutting edges for soft and medium hard wire

- Without bevel, for flush cutting

- Low-friction double spring for gentle and even opening

- Sturdy, zero backlash box joint

- The polish together with a fine film of oil offer effective rust protection - no circuit faults caused by peeling chrome from plated tools

- Cutting edges additionally laser-hardened, cutting edge hardness approx. 56 HRC

Technical attributes

Article No.

62 12 120

EAN

4003773048008

Head

polished

Handles

with multi-component grips

Weight

70 g

Dimensions

120 x 67 x 17 mm

Standard

DIN ISO 9654

REACH compliant

does not contain SVHC

RoHS compliant

not applicable

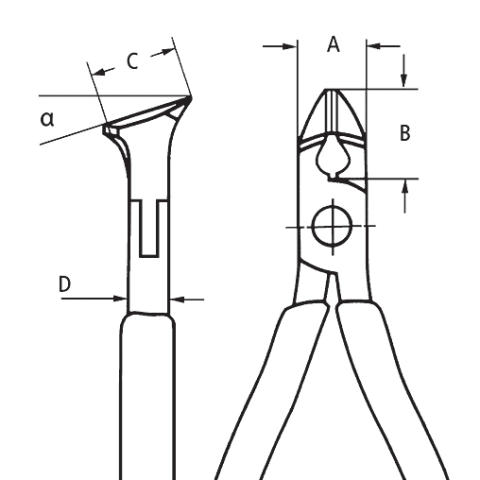

Ø 0.7 mm

Jaw length (B)

10 mm

Jaw thickness (joint) (D)

7.5 mm

Cutting edge length mm (C)

17 mm

Head width (A)

11 mm