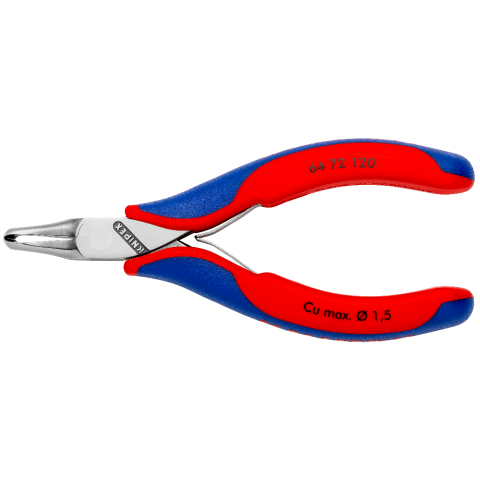

64 72 120Electronics End Cutting Nipper

- Precision pliers for ultra fine cutting work, e. g. in electronics and fine mechanics

- Sturdy, zero backlash box joint

- Low-friction double spring for gentle and even opening

- The polish or mirror polish together with a fine film of oil offer effective rust protection - no circuit faults caused by peeling chrome from plated tools

- Cutting edges additionally laser-hardened, cutting edge hardness approx. 56 HRC

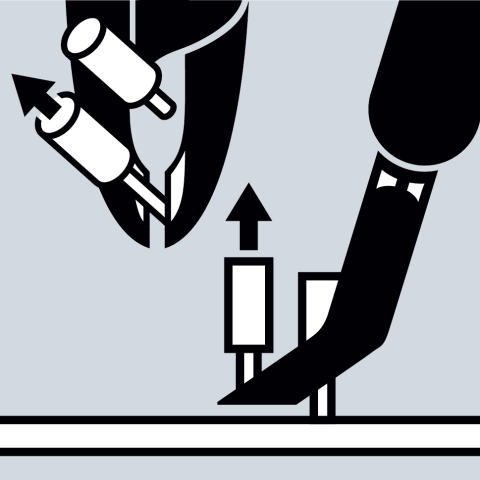

Cut fine wire and cable at an angle of 35° to the surface

Cutting from the front at an angle of 35° to the surface – also almost flush

In tight spaces, e.g. on printed circuit boards, cutting is often best done from above. Unlike with diagonal cutters, where the cutting edges are a relatively straight extension of the handle, the cutting edges of these electronics end cutting nippers are at an angle of 35° to the handles. This permits work that is almost vertical to surfaces from which wire, cable or components are protruding. The power delivery to the cutting edges and the measuring of manual force are both excellent thanks to the good leverage resulting from the short pliers head. The small bevel makes almost flush cutting possible. Due to their design, these electronics end cutting nippers are only suitable for soft wire.

Sophisticated design – designed for ergonomics and durability

These Knipex electronics end cutting nippers have a smooth operating box joint with zero backlash. Box joints are characterised by the fact that the inner handle is guided on both sides by two extensive bearing surfaces in the outer handle. This prevents the tilting movements which are typical with lap joints, and has a positive effect on the quality of cutting processes and tool life. In addition to oil hardening of the entire pliers, the cutting edges are induction hardened to at least 60 HRC. The low friction double spring is an advantage ergonomically. It produces a gentle, steady opening after cutting.

High Knipex quality standards and safety rust protection

Instead of chrome-plating, the Knipex 64 72 120 electronics end cutting nippers have a mirror polish and a fine oil film as corrosion protection. With occasional re-oiling of the surface, this rust protection is completely sufficient for workshop operation. As a result, these electronics pliers are also ideal for sensitive electronics environments for safety reasons. There are no pieces of chrome that could peel off and disrupt circuits. The quality machining of the pliers meets the requirements present in electronics and micromechanics: precision, function and reliability are at the top of the list.

Electronics pliers for the finest cutting work e.g. in electronics and precision engineering

Cutting capacity: soft wire Ø 1.5 mm; designed for soft wire only

Precision box joint

High-grade special tool steel, forged, oil-hardened

Head with recess; mini cutting edge with small bevel; additionally induction hardened, cutting edge hardness at least 60 HRC

Handles with multi-component grips

Length 120 mm

Net weight 95 g

Knipex End cutting nippers – precision for electronics and precision engineering

Knipex offers an extensive range of end cutting nippers for applications in electronics and precision engineering. They are characterised by high precision and functionality – and the long life that Knipex stands for.

Those who use tools a lot and professionally every day expect a quality that permits simple and safe work and which lasts for many years of hard use. These electronic end cutting nippers are forged from quality materials, carefully machined and heat treated.

Every pair of Knipex pliers represents more than 130 years of specialist know-how.