87 11 250KNIPEX Cobra®...maticWater Pump Pliers

- All features of the KNIPEX Cobra® 87 01 250

- Automatic adjustment at the touch of a button directly on the workpiece

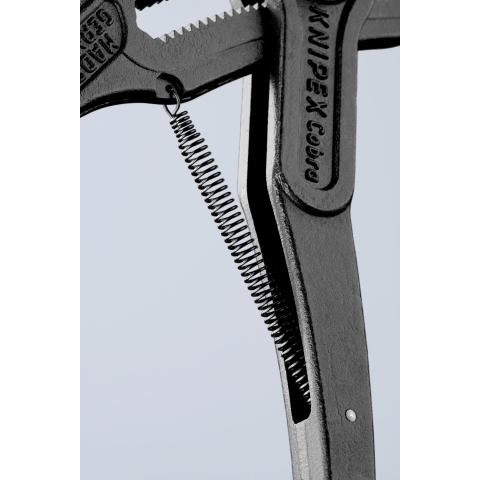

- The sheltered positioned spring ensures that the pliers close automatically once the push-button is activated (one-hand operation!)

The high-tech water pump pliers

Grip quickly, adjust finely

The benefits of working with the Knipex Cobra are plain to see: these water pump pliers are light and stable, can be adjusted on the component quickly using the automatic spring and are self-locking on pipes and nuts. The pliers close by themselves at the touch of a button thanks to the protected spring.

For pipes, nuts, sleeves, for various kinds of components: apply the Knipex Cobra…matic quickly and accurately with just one hand movement. The spring-loaded hinge bolt locks securely into place without adjusting inadvertently. Thanks to the 25-fold fine adjustment, the Cobra…matic can be ideally adjusted to different sizes of component. This fine adjustment also makes sure that the distance to the handles remains hand-friendly for every opening width.

Tough and strong

The Knipex Cobra…matic is further stabilised by the box joint design. Unlike pliers with mounted joints, no tilting forces arise here when under strain. The handles stabilise each other in the joint.

Self-locking mechanism ensures a high degree of efficiency

The Knipex Cobra…matic clamps onto the component by itself thanks to the jaw geometry developed by Knipex. This means the user can put all energy into the desired movement without pressing the pliers handle together – and thus without energy loss: round components can be turned, bolted connections tightened and released.

Modern high performance water pump pliers

One-handed operation thanks to automatically closing spring which is activated at the touch of a button

25-fold fine adjustment for fast adjustment to different sizes of component

Self-locking on pipes and nuts

Large grip width (up to a wrench opening of 46 mm / pipes up to 2 inches) with low weight (335 g)

Gripping teeth hardened to approx. 61 HRC using high frequency for a secure grip and a long service life

Grips flat, round and angled components

High level of user comfort due to constant hand-friendly gripping position resulting from fine adjustment

Sits firmly in the hand thanks to non-slip handles

Chrome vanadium electric steel, forged, oil hardened

Knipex Cobra: several manufacturing steps for high tool quality

We forge the Knipex Cobra from chrome vanadium steel, and use a multiple stage hardening process to give it the ideal balance between hardness and toughness. This makes it extremely durable. To achieve a lasting secure “bite” on the work component, we use high-frequency current to bring the gripping teeth to a hardness of approx. 61 HRC.

Professional users expect a tool quality that will last for many hard years of work. We develop and manufacture our pliers for the most demanding users imaginable: for craftsmen. Every pair of pliers from Knipex is manufactured to the highest standards using the best materials. A purchase for many years of use during assembly work, on the building site, in production and in the workshop.

Convenient and fast: fine adjustment at the touch of a button

The pliers close automatically due to the protected springs

Self-locking effect due to special jaw geometry: firm hold of the component even under heavy loads

Has a self-locking grip on various sizes of flat, round and angular components