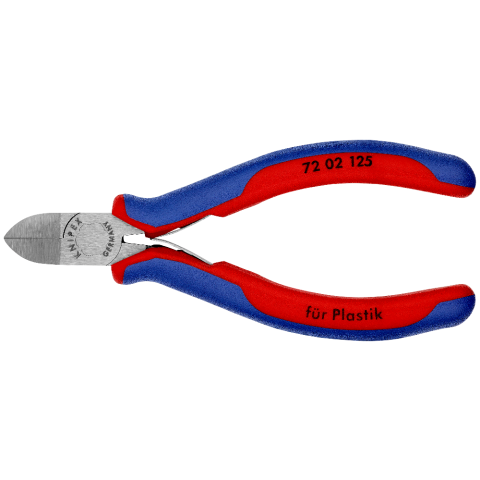

72 02 125Diagonal Cutters for plastics

- Cutting face flush

- For nearly flush cutting of moulded plastic components from sprues

- Cuts soft materials such as lead in a flush cut

- With opening spring

Small diagonal cutters for plastic and other soft materials

Why special diagonal cutters are needed for plastic

The cutting edges of classic diagonal cutters are ground to produce a wedge-shaped cut towards the centre of the cut product. This wedge actually splits the cut material apart, and the wire ends have wedge-shaped cut surfaces. A flush, smooth cut is desired when separating moulded parts and sprues, however, in order to create the least finishing work when deburring. Diagonal cutters for processing plastic must not have any bevel towards the component to create a straight cut surface. The Knipex 72 02 125 diagonal cutters have been specially developed for plastics and other soft materials. Their cutting edges are surface ground.

For flush deburring after injection moulding, for model making

The Knipex 72 02 125 are the smallest Knipex diagonal cutters for plastic. They are used when moulded parts need to be mechanically separated from sprue after demoulding. They are also suitable for delicate work, e.g. in model making. Their surface ground cutting faces produce a clean, flush separation of extruded plastic injection moulds and sprues or sprue residues. The sprue is cut off directly on the moulded part, because the cutting edge runs parallel to the component.

With opening spring to relieve strain on the user – compact and stable

The opening spring makes work easier for the user, especially where work steps repeat frequently. Users, who often deburr plastic parts in 3D mould construction for example, therefore appreciate the opening spring. At 125 mm long and with a weight of 109 g, the 72 02 125 are the smallest diagonal cutters for plastics from Knipex. Although these mini diagonal cutters fit in any pocket, when it comes to durability they are as good as any other diagonal cutters for plastics from this range. We forge the Knipex 72 02 125 from vanadium electric steel and give them high strength by warming them and then quenching them in oil.

Mini diagonal cutters for plastic and soft materials such as lead

For delicate work, e.g. in model making

For the smooth, flush cutting of sprue as arises during injection moulding

Surface ground cutting edges (no chamfer)

Handles with multi-component grips

Vanadium electric steel, forged, oil hardened

Head with precision finish

Length 125 mm

Net weight 109 g

Knipex diagonal cutters for plastic and soft materials

One can see how good diagonal cutters are by the cut. This also applies when cutting plastic. In addition to the quality forged metal parts made of vanadium electric steel, the most important quality criteria at Knipex include the precise machining of the tool steel manufactured in Germany. The material to be cut is cut flush using the surface ground cutting edges.

Thanks to their long tool life, Knipex diagonal cutters produce permanently accurate cuts.