78 71 125Electronic Super Knips®

- Precision pliers for ultra fine cutting work, e. g. in electronics and fine mechanics

- Ground, very sharp cutting edges without bevel

- Precisely shaped tips cut wires close to a surface from Ø 0.2 mm

- Shear cut with controlled micro cutting edge misalignment for the most precise cutting of even the thinnest of wires and for a long service life

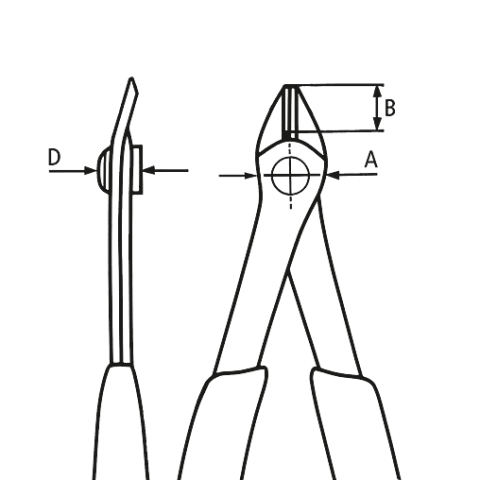

- Joint with stainless steel rivet

- Extremely smooth movement for minimum operator fatigue

- With opening spring and opening limiter

- With lead catcher - no uncontrolled loss of cut wire ends

- Cutting edges additionally induction-hardened, cutting edge hardness approx. 62 HRC

- Special tool steel, burnished

Accurately cut abutting, fine wire and fibre optic cables

Extremely sharp cutting edges made of induction hardened special tool steel

The Knipex Electronic Super Knips is manufactured from special tool steel and polished. The cutting edges are ground without bevel for flush cutting and are induction hardened to approx. 64 HRC.

Accurately cut fine wires, e.g. that are touching enclosures and components, thanks to precision tips.

Work involving dexterity: low weight and smooth operation

Great dexterity is needed when working on electronic components and in precision mechanics. Due to its frictionless handle spring, the Knipex Electronic Super Knips 78 71 125 is so smooth-running that energy can be metered out very precisely – with dexterity. Opening spring and opening restrictor simplify work further.

The integrated wire clamp prevents wire sections from springing back in an uncontrolled manner: a safety aspect, particularly when cutting wires in enclosures containing electronic assemblies.

A special detail ensures an accurate cut and long service life

These precision pliers have been designed so that the user is able to concentrate completely on his work, also when working continuously, without the need to consider the tool.

One special detail permits the most precise shear cuts on even the thinnest of wire, and at the same time gives the pliers a long service life: the extremely sharp cutting edges on the Electronic Super Knips 78 71 125 are protected against bumping into each other after cutting by the micro cutting edge misalignment.

It is therefore clear that these pliers with their ergonomically shaped multi-component grips will sit comfortably in the hand for many years.

Precision pliers for the finest cutting work in electronics and precision engineering: shear cut with controlled micro cutting edge misalignment

Thanks to precisely shaped tips, also cut abutting wires accurately as from Ø 0.2 mm

Cutting capacity of soft wire up to 1.6 Ø mm; medium-hard wire up to 1.2 Ø mm

Also cuts single conductors on fibre optic cables

Multi-component grips

Very smooth operating thanks to frictionless handle spring

Low weight (57 g)

Manufacture in accordance with high standards for optimum work results and a long tool life

Manufactured from polished special tool steel

Wire clamp holds wire sections on the pliers and thereby prevents them springing back

Cutting edge hardness approx. 64 HRC

Knipex 78 71 125 Electronic Super Knips: high level of safety and quality

The Knipex Electronic Super Knips are used for the finest cutting in electronics, precision engineering and communications engineering, and are highly valued by radio technicians, industrial electricians, mechatronics engineers and electronics engineers. These precision pliers offer the following benefits: particularly smooth operation, low weight, outstanding cutting precision and long tool life, among other things thanks to micro-cutting edge misalignment. These advantages are the visible results of decades of experience in toolmaking, continuous development and Knipex’s commitment to high quality standards: from material selection and processing through to finishing.