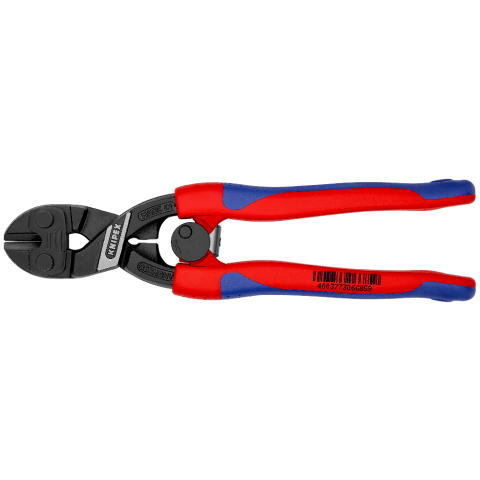

71 12 200KNIPEX CoBolt®Compact Bolt Cutters

- With precision cutting edges for soft, hard and piano wire

- Cuts bolts, nails, rivets, etc. up to Ø 5.2 mm

- Efficient joint design ensures exceptional cutting performance with little effort

- Cutting edges additionally induction-hardened, cutting edge hardness approx. 64 HRC

- Micro-structured cutting edge reduces slipping of the material from the jaws

- With gripping surface below the joint for gripping and pulling wires from Ø 1.0 mm

- With slim multi-component grips without collar for better handling and easier transport

- Opening spring and locking device are integrated in the handles for comfortable work and safe transport

Muscle man in trouser pocket format

The Knipex 71 12 200 Cobolt compact bolt cutters with integrated opening spring protects your hand

Small tool, big impact – those used to working with standard bolt cutters will appreciate how user-friendly the CoBolt 71 12 200 is. Thanks to their practical size of 200 mm and low weight of less than 400 g, the strong compact bolt cutters are quickly at hand and are also a powerful partner in demanding situations. Even the hardest wire is no problem, and they master piano wire up to a diameter of 3.6 mm reliably. When cutting bolts, nails and rivets up to a diameter of 6 mm (in the case of soft material), you benefit from maximum power and convenient handling.

Integrated opening spring – particularly pleasant for heavy use

While working, the well-designed opening spring on the CoBolt 71 12 200 repeatedly opens the cutters automatically, thereby saving many small hand movements that might tire and irritate joint muscles. In particular this substantially eases work above head height

The high cutting performance is the result of long-standing engineering experience. The precision cutting edges made of chrome-vanadium high-performance steel are induction hardened and therefore guarantee the greatest cutting edge hardness. The particularly efficient lever action mechanism guarantees an extremely favourable lever ratio with simultaneously low friction. The CoBolt reinforces the hand force used to grip the handles 35 times over.

Microstructures for maximum cutting effect

Every cut hits the mark straightaway: microstructures on the cutting edges hold the material in the perfect position, allowing the leverage of the CoBolt to take full effect: one cut – done! At the same time, the handles with multi-component grips are non-slip and guarantee they are pleasant to use even for long periods. The two materials with different degrees of hardness ensure an optimum distribution of acting forces.

Knipex quality: the Cobolt 71 12 200 compact bolt cutters are manufactured in the Knipex factory in Wuppertal-Cronenberg using quality materials. As with the other models of pliers from the Knipex think tank, they stand for top quality and therefore - when used correctly - also for exceptional durability. Their ergonomic shape furthermore means they offer the best possible conditions for gentle and safe use.

Powerful cutting due to efficient joint design

Reinforce manual force 35 times over

Suitable for large cross sections up to 6 mm

Cuts through hard materials up to Ø 4 mm, and even piano wire up to Ø 3.6 mm

Up to 60% energy-saving compared to high leverage diagonal cutters of the same length

Induction hardened cutting edges

Microstructures for the very precise positioning of the material

Gripping surface to pull wire, remove nails etc.

Perfect handling thanks to handles with slim multi-component grip

Extremely favourable lever ratios

High performance chrome vanadium steel

Made in Germany

The CoBolt can do more than cut – it can also grip and pull

The useful gripping surface directly below the joint makes the Knipex CoBolt even more versatile. This function enables farmers, landscape gardeners, forestry workers or fencing contractors and others to grip and pull: simply take hold of the wire by the gripping surface, hold the CoBolt like a T-iron, and already it is possible to apply high tensile forces, for example to tension wire as from a diameter of 1 mm.

In addition, the gripping surface may be used as a lever to remove twisted nails or staples - for example in construction, drywall installation, carpentry, fencing or demolition work.

Comfortable work

The integrated opening spring with locking function guarantees comfortable working and safe transport.

Reliable cutting

The microstructures on the cutting edges secure the material. This enables materials with large cross-sections to be cut through perfectly.

Excellent cutting capacity

The need to reapply the tool with large diameters is prevented by the microstructured cutting edges. Leverage is fully utilised right from the start.

Secure gripping

Thanks to the handles with multi-component grip, the Cobolt always sits securely in your hand so that you are able to cut any material powerfully.