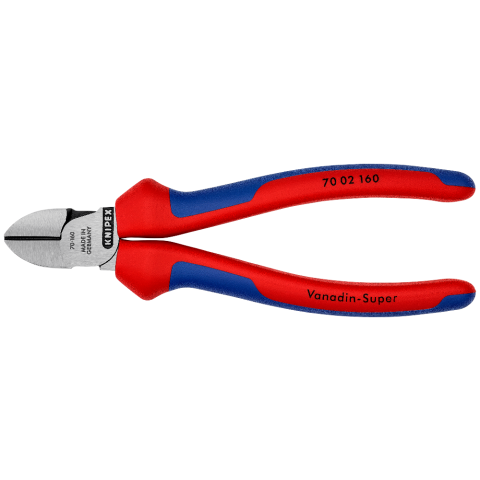

70 02 160Diagonal Cutter

- Narrow head style for use in confined areas

- The indispensable diagonal cutter for all-round use

- High-quality material and precise workmanship for long service life

- Precision cutting edges for soft and hard wire

- Clean cutting of thin copper wires, also at the cutting edge tips

- Cutting edges additionally induction-hardened, cutting edge hardness approx. 62 HRC

- With elongated cutting edge

The versatile diagonal cutters, 160 mm long

Optimised for the craftsman’s everyday work

Long appreciated by many craftsmen – the Knipex diagonal cutters with a length of 160 mm are a classic in the Knipex range.

From the shape of the head through to the polish and hardness of the cutting edges, it is customised for the diverse cutting tasks in the day-to-day work of electricians and mechatronics engineers.

Universal cutting capacity

With their cutting capacities of up to Ø 2.0 mm on hard wire (e.g. wire rope fibre) and up to Ø 4.0 mm on soft wire (e.g. copper wire), the Knipex 70 02 160 diagonal cutters offer a broad range of applications.

The long cutting edges make them ideal for cutting cable. The extremely carefully and precisely machined cutting edges enable even very fine stranded wire to be cut accurately – up to the tips of the cutting edges.

This is a great advantage where space is restricted, for example when shortening fine stranded wires in junction boxes.

Tough and durable

We forge the Knipex diagonal cutters from vanadium electric steel and make them strong by warming them and then quenching them in oil.

To achieve a permanently accurate cut we additionally use high-frequency current to give the cutters a hardness of approx. 62 HRC. Thanks to the multi-component grips, the handles are non-slip and very comfortable.

Versatile diagonal cutters

Cut hard wire (e.g. wire rope fibre) up to Ø 2.0 mm and soft wire (e.g. copper wire) up to Ø 4.0 mm

Precise cutting also of fine CU wire, even with the tips of the cutting edges

Are also suitable when working in confined spaces thanks to their slim head shape

Production according to higher standards for optimal work results and a long service life

Cutting edges hardened to approx. 62 HRC for strength and a long tool life

Handles with multi-component grips

Vanadium electric steel, forged, oil hardened in multiple stages

Knipex diagonal cutters: precise cuts right up to the tips of the cutting edges

One can see the quality of diagonal cutters by their cut. Knipex diagonal cutters deliver lasting high performance. In addition to the quality forged metal parts made of vanadium electric steel, the most important quality criteria at Knipex include the precise machining of the tool steel manufactured in Germany.

The material is cut cleanly. The length and sharpness of cutting edges are geared to high performance on the Knipex 70 02 160 – even in confined spaces. The high quality and degree of hardness of the cutting edges guarantees a long service life.

Cutting edges additionally induction hardened, cutting edge hardness approx. 62 HRC.

Quality material and precise machining for a long tool life.

Accurate cut right into the tips of the cutting edges.

Precision cutting edges for soft and hard wire.