97 52 13Crimping PliersFor two-hand operation

- For solder-free electrical connections

- The ingenious lever transmission reduces the handforce up to 30% compared with regular crimping pliers

- Consistently high crimping quality due to precision dies and ratchet mechanism (unlockable)

- Tools have been set precisely (calibrated) in the factory

- Two-hand operation for easy crimping of large conductor diameters

- Easy handling as a result of well balanced centre of gravity, angled head and ergnomically shaped handles

- Crimping die is not exchangeable

Extremely user-friendly: precision requiring little time and effort

Professional crimping results –the ideal crimping pressure automatically

The crimping of non-insulated cable lugs and connectors requires a great deal of care in order to create safe electrical connections. Normally. The Knipex 97 52 13 crimping pliers are a tool that intuitively helps the user do everything right.

Non-insulated crimp, tubular and compression cable lugs and non-insulated crimp, butt and press connectors are reliably crimped to the conductors in the precision-machined crimp profiles. The integral lock ensures that the pliers only open once the optimal crimping pressure set in the factory has been reached. The crimping pressure can be adjusted; the integral lock can be released if need be.

30 % less effort required – the leverage principle is used twice

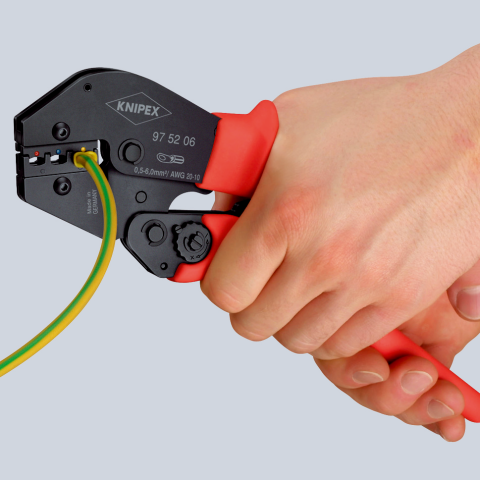

Double use of the leverage principle – twice the relief from strain: up to 30 % less effort required compared to conventional crimping pliers, made possible by applied physics. The handles of the Knipex 97 52 13 are shaped to produce a long lever arm. This also permits two-handed operation for large conductor cross-sections. Special leverage is also integrated in the crimping pliers, so that even a low level of manual force gets to the conductor in a carefully measured way. The user can professionally produce stable connections from conductors and cable lugs or connectors with little time and effort.

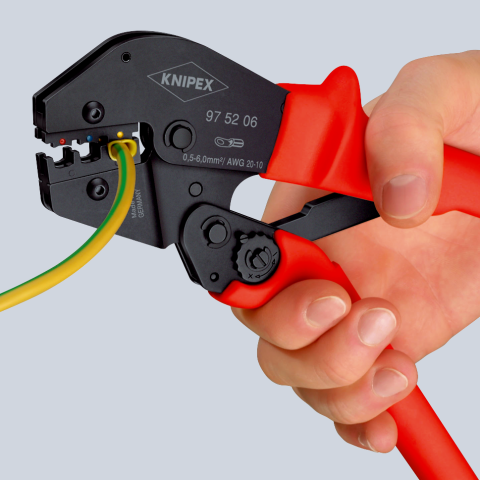

This is how it is done: three hand movements to produce a professional crimp connection

A non-insulated crimp, tubular and compression cable lug or a non-insulated crimp, butt and press connector is inserted in the corresponding precision die. The lower handle is pulled up using two fingers, until both jaws are resting on the cable lug or connector to be crimped, thereby fixing it in the crimp profile. After inserting the stripped cable, crimping is carried out: reliably and securely. The Knipex 97 52 13 has been designed for many years of use. The high Knipex quality standards and selection of materials with high-grade chrome vanadium electric steel ensure that all the qualities of these crimping pliers will last for a long time.

Extremely user-friendly crimping pliers with lever transmission

For non-insulated crimp, tubular and compression cable lugs in accordance with DIN 46234 and DIN 46235, as well as non-insulated crimp, butt and press connectors in accordance with DIN 46341 and DIN 46267 with a capacity of 0.5 – 10.0 mm²

Long lever arm for one-handed and two-handed operation

Toggle lever system for high efficiency

Integral lock (with release mechanism) only triggers on reaching the optimal crimping pressure

Consistently high crimping quality due to (adjustable) crimping pressure calibration

Firm grip in the hand thanks to ergonomic shape of the handle

Chrome high-grade vanadium electric steel; oil-hardened

Handles with non-slip plastic grips

Length 250 mm

Net weight 558 g

Durable and accurate

The precision die with two crimping dies made of high-grade chrome vanadium electric steel is very stable

Easier crimping of large cross-sections

30% less manual force compared to conventional crimping pliers thanks to the toggle lever transmission plus the option of two-handed operation ensure a low level of work fatigue.

Professional crimping result

Consistently high crimp quality and integral lock with release mechanism

For calibration inquiries, please contact our affiliated company RENNSTEIG WERKZEUGE GMBH under the following contact:

Mr. Uwe Wagner

Tel .: +49 36 847 441-59

Domestic sales

![]()