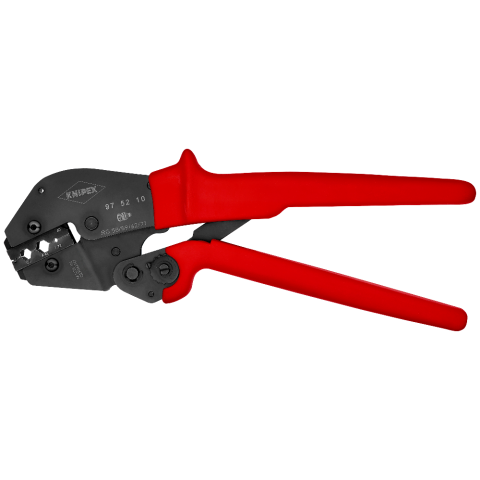

97 52 10Crimping PliersFor two-hand operation

- For solder-free electrical connections

- The ingenious lever transmission reduces the handforce up to 30% compared with regular crimping pliers

- Consistently high crimping quality due to precision dies and ratchet mechanism (unlockable)

- Tools have been set precisely (calibrated) in the factory

- Two-hand operation for easy crimping of large conductor diameters

- Easy handling as a result of well balanced centre of gravity, angled head and ergnomically shaped handles

- Crimping die is not exchangeable

Extremely user-friendly: precision requiring little time and effort

Intuitively achieve professional crimping results

The crimping of connectors in communication electronics must be learned in order to create connections that are mechanically secure and electrically interference-free. You also need tools that are very precisely matched to connector and coax cable for a good quality crimp connection where the conductor is crimped with the central contact and where the cable is crimped with the connector using the connector sleeve braiding in an electrically safe and mechanically secure way. By contrast, no prior knowledge is needed when using the Knipex 97 52 10 crimping pliers, which give the user a tool that intuitively helps him do everything right. BNC and TNC COAX connectors are reliably crimped to the central conductor and braiding in the precision-machined crimp profiles. The integral lock ensures that the pliers only open once the optimal crimping pressure has been reached. The crimping pressure is calibrated in the factory and can be adjusted; the integral lock can be released where necessary.

30 % less effort required – the leverage principle is used twice

Thanks to double use of the leverage principle, up to 30 % less effort is required compared to conventional crimping pliers. The length of the handles on the Knipex 97 52 10 produces a long lever arm and sufficient space for two-handed operation. Special leverage is also integrated in the crimping pliers, so that the user can produce stable connections from RG 58 / 59 / 62 / 71 / 223 coax cables and BNC and TNC COAX connectors with little time and effort.

This is how it is done: three hand movements to produce a professional crimp connection

Once the sheathed crimp sleeve has been pushed over the COAX cable that has been stripped in two stages, the central contact pin of a BNC or TNC COAX connector is inserted in the smallest crimping die. The lower handle is pulled with two fingers until both jaws lie on the central contact pin to be crimped, so holding it in the crimp profile. After inserting the cable core (central contact) of the prepared coax cable, the crimping operation for the central contact is carried out. The connector is then guided over the central contact and pressed as far as it can go towards the step of the inner conductor insulation against the cable end.

The shielding braid is then combed forwards over the bushing on the connector and the sheathed crimp sleeve is pushed forwards over the shielding braid until it comes up against the connector housing.

A connection that is electrically interference-free and is mechanically secure is then established by crimping the sheathed crimp sleeve to the connector and the cable in the hexagonal profile that is suitable for the connector.

The high KNIPEX quality standards and selection of materials with high-grade chrome vanadium electric steel ensure that all the high tool qualities needed will last for a long time.

Particularly user-friendly crimping pliers with lever transmission

For BNC and TNC COAX connectors

Long lever arm for one-handed and two-handed operation

Toggle lever system for high efficiency

Integral lock (with release mechanism) only triggers on reaching the optimal crimping pressure

Consistently high crimping quality due to (adjustable) crimping pressure calibration

Knipex quality standards guarantee ideal work results and a long service life

Firm grip in the hand thanks to ergonomic shape of the handle

Chrome high-grade vanadium electric steel; oil-hardened

Handles with non-slip plastic grips

Length 250 mm

Net weight 577 g

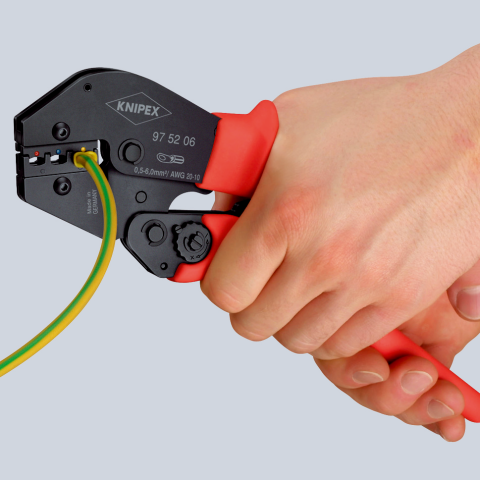

Positioning of the central contact pin

The central contact pin is placed in the smallest crimp form; the core of the cable (central contact) is inserted.

First crimping operation: central contact

Central contact pin and central contact are crimped. The pliers open when there is the optimal crimping pressure (integral lock).

Secure crimp connection

The integral lock ensures the ideal crimping pressure; precision crimp profiles produce [mechanically and electrically] safe and secure connections.

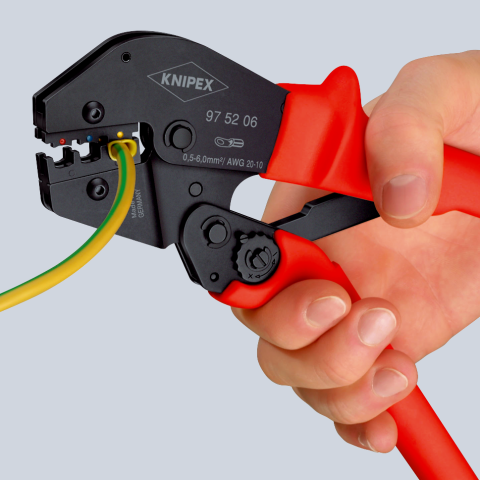

Insertion of crimp sleeve, connector and cable

The shielding braid and the sheathed crimp sleeve are prepared; the sheathed crimp sleeve has been pushed against the connector housing

Second crimping operation:

The sheathed crimp sleeve, the connector and the cable are securely crimped to each other in the hexagonal profile that is suitable for the connector.

Crimp connection successful

Permanently safe connections because the integral lock only triggers when there is the ideal crimping pressure.

For calibration inquiries, please contact our affiliated company RENNSTEIG WERKZEUGE GMBH under the following contact:

Mr. Uwe Wagner

Tel .: +49 36 847 441-59

Domestic sales

![]()