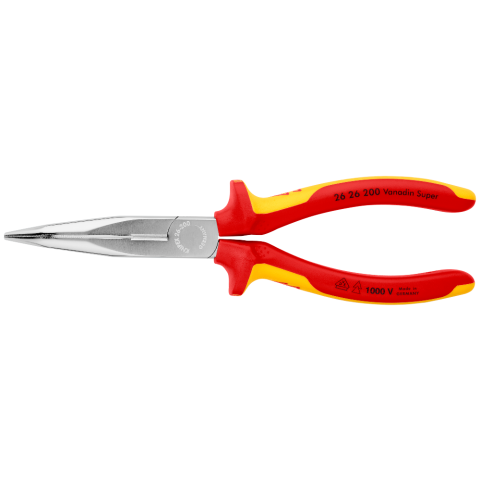

26 26 200Snipe Nose Side Cutting Pliers(Stork Beak Pliers)

- Half-round, long, tapered jaws

- Distortion-tolerant, elastic precision tips

- Suitable for finer gripping and cutting work, also on easy and semi-difficult to reach areas

- With cutting edges for soft, medium-hard and hard wire

- Cutting edges additionally induction-hardened, cutting edge hardness approx. 61 HRC

Pliers for professional users from the electrical/installation trade

VDE tested: for installation and assembly tasks, as well as cutting

These forged, oil-hardened and insulated stork beak pliers with multi-component grip are ideal for installation, insertion and assembly, as well as powerful cutting. The cutting edges of the pliers are shaped to produce a pierced cut. The Knipex 26 26 200 also cuts hard wires.

Dimensionally stable under torsion – very powerful when cutting

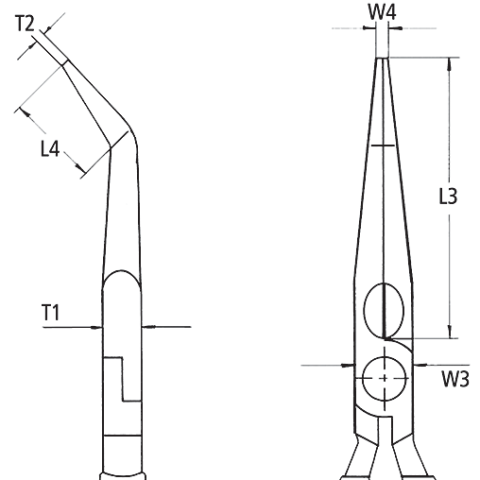

The flexible precision tips made of vanadium electric steel are torsion-resistant and angled 40°. The pliers allow you to control the manual force. The cutting edge position near the joint favours the transmission of force. This results in impressive cutting values for medium-hard wire of up to 3.2 Ømm and for hard wire of up to 2.2 Ømm.

Components and wires are easily accessible in control cabinets, machines or electric motors

Whether connecting wires to conductor terminals, in junction boxes or in control cabinet construction – the extra-long tips of the VDE tested stork beak pliers from Knipex 26 26 200 allow you to work efficiently, especially when space is tight. Their qualities are appreciated whenever cables and wires need to be held, inserted or cut.

Snipe-nose pliersfor assembly, adjustment & gripping electronics

Very long, narrow, half-round jaws, 40° angle at the tips

End cutting; wire cutting values: medium-hard Ø3.2 mm, hard Ø2.2 mm

Forged from vanadium electric steel, cutting edges hardened to approx. 61 HRC

Chromed pliers

Insulated, multi-component grips

VDE tested

Knipex quality – VDE tested stork beak pliers

The Knipex VDE tested stork beak pliers are specially designed for installation and assembly work in hard-to-reach areas in the electrical trade. Professionals who use tools every day expect a quality that enables them to work easily and safely and that can withstand many years of tough service.

We produce our tools from high-quality materials, processing them with high precision on modern machine tools and hardening them through careful multiple heat treatments.