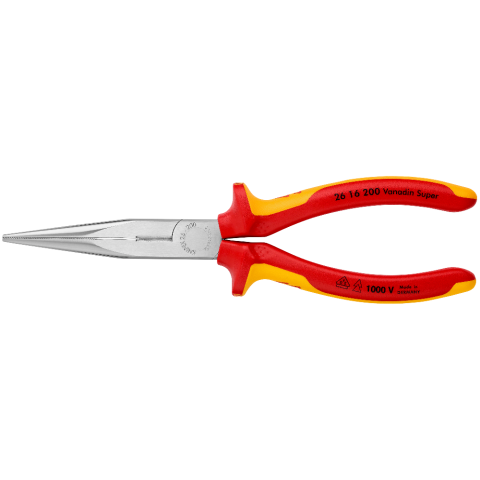

26 16 200Snipe Nose Side Cutting Pliers(Stork Beak Pliers)

- Half-round, long, tapered jaws

- Distortion-tolerant, elastic precision tips

- Suitable for finer gripping and cutting work, also on easy and semi-difficult to reach areas

- With cutting edges for soft, medium-hard and hard wire

- Cutting edges additionally induction-hardened, cutting edge hardness approx. 61 HRC

VDE tested needle nose pliers for electricians and fitters

The pliers for professional installation and assembly work, and for cutting

The Knipex 26 16 200 is primarily used by electricians carrying out installation, wire feeding and assembly work and who also want a professional cutting function on the pliers. The cutting edges of the pliers are shaped to produce a bite type cut. The cutting edges are additionally induction hardened to approx. 61 HRC so that the pliers can even be used to cut hard wire.

Inherently stable also where there is twisting and very strong when cutting

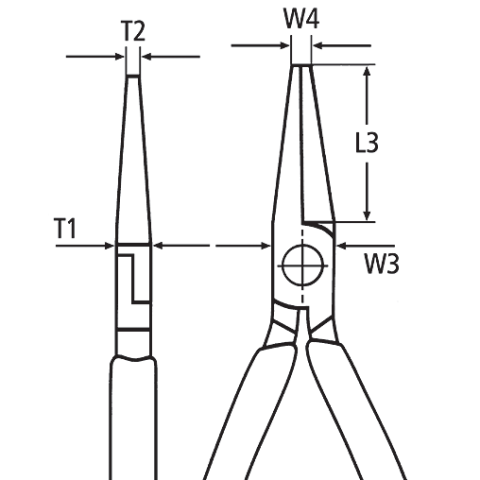

The precision tips made of vanadium electric steel are elastic and stable when twisted. This allows the manual force deployed using these pliers to be well measured, which is a particular benefit with delicate components. The needle nose pliers can also be used for powerful gripping and holding – and for cutting. Thanks to the position of the cutting edges near the joint which is advantageous for the transmission of force, good cutting capacities are achieved. Medium-hard wire can be cut up to Ø 3.2 mm and hard wire up to Ø 2.2 mm.

Components and wire in unfavourable positions can also be reached well

In the control cabinet, on a machine, on an electric motor, when feeding and connecting wire to terminals, in junction boxes, in control cabinet construction: the VDE tested Knipex 26 16 200 is in its element wherever space is tight. The qualities of the snipe nose side cutting pliers from Knipex will be immediately apparent when lines and wires need to be held, fed and cut. The quality chrome plating offers good protection against dirt and corrosion. This corrosion resistance makes special sense when the pliers are kept permanently in the service vehicle, where they may be exposed to condensation caused by temperature changes.

Needle nose pliers (stork beak pliers) for assembly, alignment and gripping work, especially in the electrical trade

Very long pointed, flat rounded jaws

Cutting edges with bite type cut for soft, medium-hard and hard wire; cutting capacity for medium-hard wire Ø 3.2 mm, cutting capacity for hard wire Ø 2.2 mm

Forged from vanadium electric steel and oil-hardened; cutting edges additionally induction hardened to approx. 61 HRC for exceptionally high cutting force

Pliers are chrome-plated

Length 200 mm

Weight 204 g

Insulated with multi-component grips

VDE tested

Knipex quality – the VDE tested snipe nose side cutting pliers

The VDE tested snipe nose side cutting pliers from Knipex are a tool especially for installation and assembly work in poorly accessible areas in the electrical trade. Those who use tools professionally every day expect a quality that permits simple and safe work and which lasts for many years of hard use.

We produce our tools from quality materials, machine them with great precision on up-to-date machinery, and harden them carefully using repeated heat treatment.

Every pair of Knipex pliers represents more than 130 years of specialist know-how.