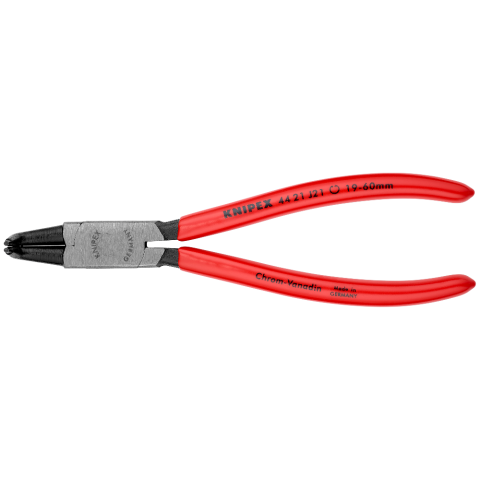

44 21 J21Circlip PliersFor internal circlips in bore holes

- Solid style, forged

- Non-slip, solid tips

Firmly grip, dismantle and fit concealed internal circlips

Accurate and stable, forged tips for an ideal hold

The precision of the pliers tips is the crucial factor when fitting and dismantling circlips, because the installation holes in the circlips offer the tips of the circlips pliers very little room for manoeuvre. The tips must overcome the ring tension and securely hold the circlip after removal or before insertion. This places high demands on the accuracy and stability of the pliers tips.

With the Knipex 44 21 J21 the handle and tips are forged in one piece, which produces correspondingly high durability. The very accurately twisted tips are also machined so they slant inwards slightly, so that the circlips are held firmly on the tips of the pliers.

Reinforced, measured manual force precisely into the installation holes

With pliers, the measurable force that reaches the component is just one of many parameters. Of prime importance is that the manual force is applied to the component in an accurate, well-measured manner. This applies especially to circlips as they are under tension when fitted and removed. Thanks to quality machining, balanced tool geometry and precise joint, manual force reaches the circlip in a manner that enables the user to work in the best way: accurately, and gentle on hands.

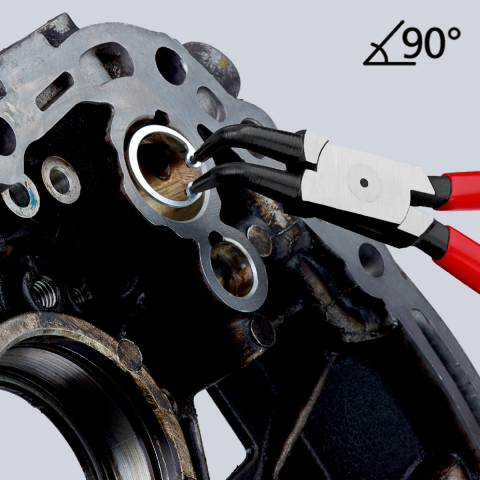

Poorly accessible circlips can be reached well thanks to angled tips

Reliable circlip pliers like the Knipex 44 21 J21 noticeably simplify work. They are narrow at the front and at a 90° angle for ideal access also to circlips that are difficult to reach. The pliers sit comfortably in the hand, can be positioned accurately in the circlip installation holes and hold the circlips firmly. Working with first-class circlips pliers such as the Knipex 44 21 J21 saves a great deal of time, as anyone who has tried to extract a circlip from a drilled hole using makeshift tools, working round corners in the process, will know. Having to search the workshop for a circlip that has sprung off because the tips of poorly machined circlip pliers have failed to hold it well can also take a long time. With the Knipex 44 21 J21, every circlip and every hand movement sits properly.

Slim circlip pliers for internal circlips in drilled holes; pliers at a 90° angle at the front

For the simple and professional fitting and dismantling of circlips in drilled holes with a diameter of 19 - 60 mm

Tough: handle and tips forged from chrome vanadium steel and hardened and tempered in oil

Non-slip, slanted, stable tips with a diameter of 1.8 mm

Pliers black, phosphate-treated; head with precision finish

Handles coated with non-slip plastic

Length 170 mm

Net weight 139 g

Circlips pliers from Knipex – every hand movement sits properly

Knipex offers an extensive range of circlips pliers for applications from precision engineering to ship engine manufacture. Those who use tools a lot and professionally every day expect a quality that permits simple and safe work and which lasts for many years of hard use.

We forge our tools from quality materials, machine them with high precision on modern machinery and harden them with careful heat treatment.

Every pair of Knipex pliers represents more than 130 years of specialist know-how.